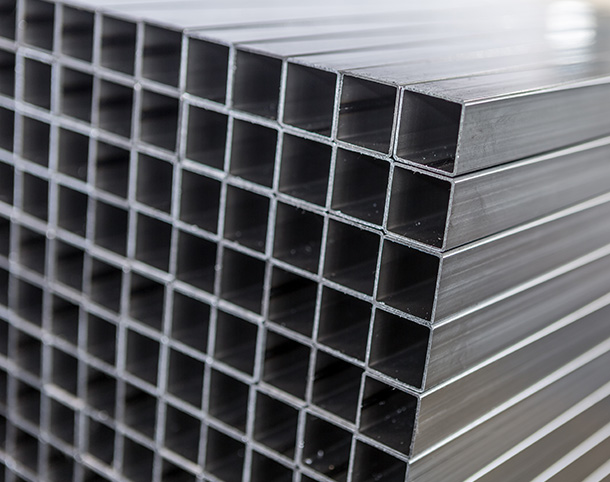

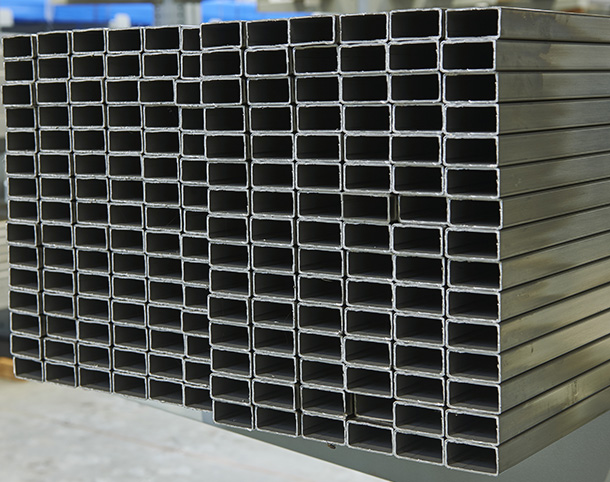

CRCA Shelving and Racking Systems are robust storage solutions constructed from Cold Rolled Full Hard steel. These systems are designed to provide exceptional strength and durability, making them ideal for industrial and commercial environments. CRCA steel's high tensile strength ensures that shelving and racking systems can withstand heavy loads without bending or buckling, ensuring the safety of stored items. Additionally, the smooth surface finish of CRCA steel enhances the appearance of the shelving and racking systems while also making them easy to clean and maintain. Whether used in warehouses, retail stores, or other facilities, CRCA shelving and racking systems offer reliable and efficient storage solutions for various applications.

- * Corrosion Resistance

- * Durability

- * Cost effective

- * Easy to Install

- * High Structural Strength

- * Versatility and can be used in various applications

- * Smooth interior surface for efficient flow of fluids

- * Aesthetic appeal

- * Longevity

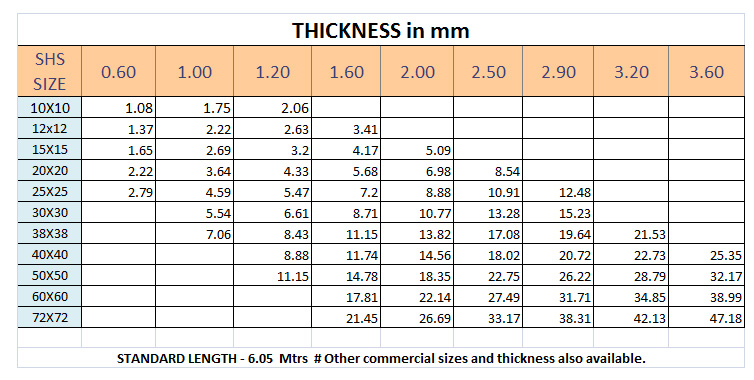

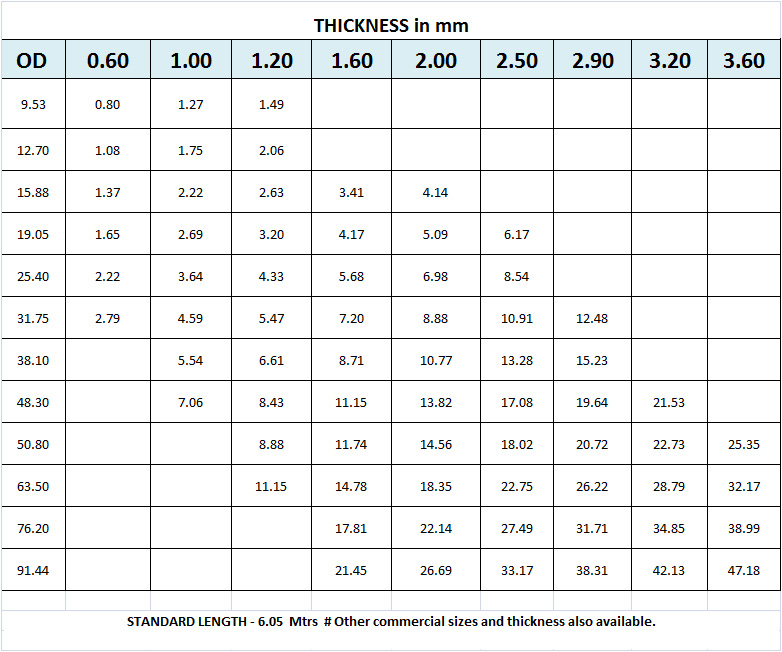

- * Available in various sizes and dimensions for various project requirements